So, you have a brilliant design idea and you’re ready to see it come to life on a mug. Whether you’re launching a small business, planning a heartfelt gift, or organizing a corporate event, one question inevitably arises: What’s the best mug printing technique?

The truth is, there’s no single “best” method. Rather, the perfect technique is the one that aligns with your vision for durability, budget, and design complexity. In other words, it’s a balancing act between art and science. With that in mind, this guide will demystify the most popular mug printing processes so that you can make an informed decision and ensure your custom mugs look fantastic while standing the test of time.

Table of Contents

ToggleThe Four Pillars of Perfect Mug Printing

Before we dive into the specific methods, let’s establish the key criteria you should be evaluating. Think of these as your checklist for success:

- Durability & Longevity: One of the biggest questions to consider is, will the design fade after 20 trips through the dishwasher, and can it handle the thermal shock of a microwave? In general, methods where the ink simply sits on top of the glaze are more prone to peeling and cracking over time. By contrast, the most durable techniques actually infuse the design into the mug or physically alter its surface, ensuring it lasts far longer.

- Print Quality & Fidelity: Another key factor to consider is the type of design you’re printing. For example, are you creating a vibrant, full-color photograph or a simple, bold logo? Ultimately, the best method for your project will be the one that can faithfully reproduce the level of detail and color vibrancy you require.

- Cost & Scalability: Are you printing a single, personalized gift or 5,000 units for a nationwide promotion? Some methods have high upfront costs that become negligible at scale, while others are purpose-built for small batches and one-off orders.

- Material Compatibility: Not all mugs are created equal. The technique you choose must be compatible with your mug’s material, be it ceramic, stainless steel, enamel, or glass.

Start Design and Sell Your Mug Today

Popular Mug Printing Methods Explained

If you’ve ever wondered how makers create vibrant photo mugs, corporate giveaway cups, or personalized coffee mugs, the secret comes down to the printing method. Each technique delivers different results in durability, print quality, and cost.

In this guide, we’ll break down the most popular mug printing methods, from sublimation to UV printing, and explain how each one works, what equipment you’ll need, and when to use it. Whether you’re starting a mug printing business, ordering promotional products, or just curious about the process, this article will give you the clarity you need.

1. Sublimation Printing

Many people use sublimation printing to customize mugs. In this method, you print your design in reverse on special sublimation paper with sublimation ink. Then, you wrap the paper around a polymer-coated mug, tape it securely, and heat it in a mug press or convection oven.

How it works: When exposed to heat and pressure, the ink turns into a gas and fuses directly into the mug’s coating. Unlike stickers or decals, the print isn’t sitting on top of the surface; it actually becomes part of the mug itself.

Key benefits:

- Durability: Sublimated mugs resist cracking, peeling, and fading. Manufacturers advertise high-quality blanks, such as ORCA-coated mugs, as microwave- and dishwasher-safe for hundreds (sometimes thousands) of cycles.

- Print quality: Perfect for full-color photos, smooth gradients, and wraparound designs. The surface stays smooth since there’s no raised ink layer.

- Cost efficiency: Low setup cost makes sublimation great for one-off orders, small batches, or personalized mugs.

- Compatibility: Works best on polymer-coated ceramic mugs, but can also be applied to certain coated metals and plastics. Raw stainless steel, glass, or uncoated ceramics will not accept sublimation dye.

Best use case: Personalized photo mugs, small business batches, and custom gifts.

2. Screen Printing

Screen printing stands as one of the most traditional techniques, using a stencil-like mesh screen. In this process, a squeegee pushes ink through the open parts of the screen to transfer the design onto the mug’s surface. Printers typically use cylindrical or rotary presses for mugs to ensure the design wraps evenly around the curve.

How it works: Each color in a design requires its own screen. Multi-color prints involve layering several screens, which makes setup more complex but allows for bold, eye-catching designs.

Key benefits:

- Durability: When ceramic or organic inks are kiln-fired or UV-cured, the print can withstand daily use and dishwashing.

- Print quality: Produces bold, opaque colors and crisp lines. Best for logos and solid designs, though not ideal for photo-realistic images.

- Cost efficiency: Higher setup cost but lower per-unit cost for bulk runs. Once screens are made, thousands of mugs can be printed quickly.

- Compatibility: Works well on glazed ceramics, bottles, and other cylindrical drinkware.

Best use case: Large promotional orders, branded giveaways, and corporate merchandise.

3. Heat Transfer Printing

Heat transfer printing uses a special transfer sheet to apply designs to a mug with heat and pressure. Unlike sublimation, where the ink fuses with the coating, heat transfer prints sit on top of the surface.

Key benefits:

- Durability: Good but less permanent than sublimation. Designs may peel or fade over time if not sealed properly.

- Print quality: Very good for high-resolution images and multi-color designs.

- Cost efficiency: Great for small custom runs, though the per-unit cost is higher than screen printing or sublimation.

- Compatibility: Works on coated ceramic mugs, glass, or metal when used with the right transfer paper. Unlike sublimation, it doesn’t always require polymer-coated blanks.

Best use case: Custom mugs in small batches, photographic designs, and promotional gifts.

4. Digital Printing (UV Printing)

Digital or UV printing is one of the most advanced mug printing methods. Instead of using transfer paper or screens, the design is printed directly onto the mug using a UV flatbed or rotary printer. The ink is instantly cured with ultraviolet light.

Key benefits:

- Durability: UV-cured inks form a strong surface layer that resists scratches and moisture.

- Print quality: Excellent for full-color, photo-quality images with fine details. UV printers can even create raised, textured designs.

- Cost efficiency: Fast setup makes it ideal for short runs and personalized gifts. Equipment costs are high, but customization flexibility is unmatched.

- Compatibility: Can print on ceramics, glass, wood, metal, and even plastics, no polymer coating required.

Best use case: Premium photo mugs, personalized gifts, and short-run custom designs.

5. Specialty Mug Printing Methods

Not every project fits into the main categories. For premium finishes or unusual designs, specialty methods like laser engraving, pad printing, and transfer decals may be the better choice.

Laser Etching / Engraving

- How it works: A focused laser beam removes part of the surface coating or marks bare metal.

- Durability: Extremely high. Designs won’t peel, fade, or wash away.

- Look & feel: Minimalist, high-end, monochrome design. Perfect for stainless steel or ceramic mugs.

- Best for: Premium gifts, corporate branding, personalized drinkware.

Ceramic Decals (Transfer Printing)

- How it works: Designs are printed on decal sheets, applied to mugs, and fired in a kiln.

- Durability: Excellent once fired; typically dishwasher safe.

- Look & feel: High detail with vibrant colors, though a faint edge line may be visible.

- Best for: Medium to large production runs, especially for ceramic mugs.

Start Design and Sell Your Mug Today

Which Mug Printing Method Is Right for You?

With so many options available, choosing the best mug printing method comes down to your purpose, budget, and design requirements. A small print shop looking to fulfill custom orders will have very different needs from a company producing thousands of corporate giveaways. Below is a breakdown of which printing techniques work best for different situations.

1. Small Businesses and Custom Orders: Sublimation or Digital (UV) Mug Printing

If you run a small shop or online store, flexibility and quality are everything. Both sublimation and digital (UV) printing are If you run a small shop or online store, flexibility and quality are everything. In this case, both sublimation and digital (UV) printing stand out as excellent choices for personalized mugs and short production runs.

Sublimation printing works best on polymer-coated ceramic mugs, producing vibrant, wraparound, photo-quality designs. Its low cost, minimal setup, and ability to handle one-off gifts or small customer orders make it especially appealing to shops just getting started.

Digital (UV) printing, on the other hand, is more versatile. Unlike sublimation, it can print directly on ceramics, glass, wood, and even metal without the need for special coatings. Additionally, the setup is fast, and the quality is outstanding—making it a smart option if you’d like to expand beyond mugs into a wider product range.

Best for: Small shops, Etsy sellers, boutique gift stores, and local printers offering personalization.

2. Bulk Promotional Orders: Screen Mug Printing

For companies producing hundreds or thousands of promotional mugs, screen printing is the clear winner.

- The upfront setup takes time because each color requires its own screen, but once the press is ready, the cost per mug drops dramatically.

- The method delivers bold, opaque logos that are built to last. Perfect for brand visibility at events, trade shows, or as corporate gifts.

Best for: Large-scale promotional giveaways, branded merchandise campaigns, and simple logo designs.

3. Premium or Luxury Gifts: Laser Engraving

When presentation matters, nothing beats the sophistication of laser-engraved mugs. In this process, a thin layer of coating is removed—or the surface of stainless steel or ceramic is etched—leaving behind a crisp, permanent mark.

The result is sleek, minimalist, and upscale, often paired with elegant gift packaging to create a lasting impression.

Best for: Executive gifts, special client appreciation, or premium merchandise for upscale brands.

4. Print-on-Demand Sellers: Sublimation

If you’re running a print-on-demand (POD) business, sublimation printing is your best ally.

- It supports full-color designs, intricate details, and photographic prints that customers love.

- Because setup is quick and affordable, you can easily offer unique, one-off designs with fast turnaround, exactly what POD customers expect.

- Plus, sublimated mugs are durable and dishwasher-safe, which helps maintain customer satisfaction.

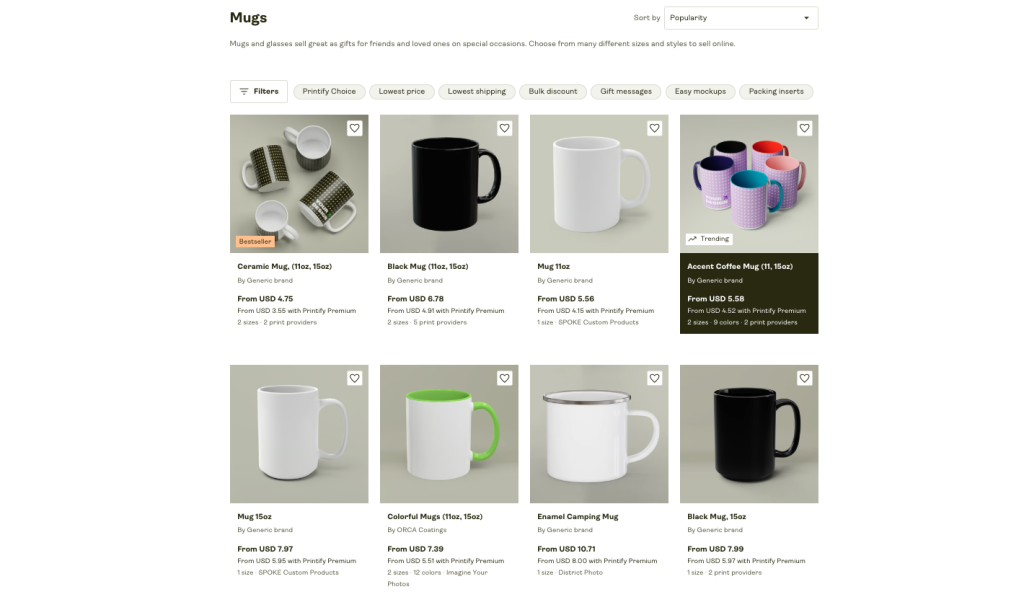

Best for: POD platforms like Etsy, Shopify, Printify, or Redbubble sellers who thrive on customization.

Start Design and Sell Your Mug Today

Final Thoughts: Choosing the Best Mug Printing Method for Your Needs

Your priorities ultimately determine the best mug printing method—whether you value durability, design complexity, cost efficiency, or the material you choose.

- Sublimation printing is your go-to if you want photo-quality, full-color designs on coated ceramic mugs. It’s durable, vibrant, and ideal for small businesses or print-on-demand sellers.

- Screen printing is the smartest option for large-scale promotional orders where bold logos and cost efficiency matter most.

- Digital (UV) printing offers unmatched flexibility across materials and delivers premium, high-resolution results, perfect for personalization and short runs.

- Heat transfer printing serves as a reliable middle ground, providing good quality at manageable costs for small to medium batches.

- Specialty methods like laser engraving or pad printing stand out when you want a luxury finish, unique shapes, or premium branding.

Whether you’re launching a mug printing business, expanding your custom product line, or simply looking to create the perfect personalized mugs for your store, there’s a method that aligns with your goals. The key is to balance your production needs with the quality and style your audience expects.

By choosing the right technique, you’ll not only get mugs that look great but also build customer trust with products that last.